Wafer Materials and Output Wavelengths

The Relationship Between Semiconductor Laser Wafer Materials and Output Wavelengths

Semiconductor lasers are widely used in various applications, including telecommunications, medical devices, and industrial processing. One critical factor determining the performance and functionality of a semiconductor laser is its output wavelength, which is directly influenced by the choice of wafer material and its associated properties. This article explores the relationship between semiconductor laser wafer materials and their corresponding output wavelengths.

1. Material Bandgap and Wavelength

The output wavelength of a semiconductor laser is determined by the energy bandgap (Eg) of the wafer material. The energy bandgap is inversely proportional to the wavelength of emitted light, as described by the equation:

λ=hcEg\lambda = \frac{hc}{E_g}

where λ\lambda is the wavelength, hh is Planck's constant, cc is the speed of light, and EgE_g is the bandgap energy in electron volts (eV). Materials with larger bandgaps emit shorter wavelengths (e.g., ultraviolet), while those with smaller bandgaps emit longer wavelengths (e.g., infrared).

2. Common Wafer Materials and Their Wavelength Ranges (Ordered by Wavelength)

Different semiconductor materials are used for lasers operating at specific wavelength ranges:

Gallium Nitride (GaN)

- Bandgap: ~3.4 eV

- Wavelength Range: ~370 nm to 450 nm (ultraviolet to blue)

- Applications: Blu-ray players, UV sterilization, and high-density data storage.

Aluminum Gallium Arsenide (AlGaAs)

- Bandgap: Tunable by aluminum composition

- Wavelength Range: ~650 nm to 850 nm (visible to near-infrared)

- Applications: Red laser pointers, CD/DVD players, and medical devices.

Gallium Arsenide (GaAs)

- Bandgap: ~1.43 eV

- Wavelength Range: ~850 nm (near-infrared)

- Applications: Optical communication, barcode scanners, and solid-state lighting.

Indium Gallium Arsenide Phosphide (InGaAsP)

- Bandgap: Tunable by composition

- Wavelength Range: ~1,000 nm to 1,650 nm (infrared)

- Applications: Tunable lasers for spectroscopy and telecommunication systems.

Indium Phosphide (InP)

- Bandgap: ~1.34 eV

- Wavelength Range: ~1,310 nm to 1,550 nm (infrared)

- Applications: Fiber optic communications and LIDAR systems.

Gallium Antimonide (GaSb)

- Bandgap: ~0.72 eV

- Wavelength Range: ~1,800 nm to 2,500 nm (mid-infrared)

- Applications: Gas sensing, medical diagnostics, and environmental monitoring.

3. Tuning the Wavelength

The output wavelength can also be tuned by engineering the wafer material. For example:

- Alloying: Adjusting the proportions of elements in compound semiconductors (e.g., InGaAsP) allows precise control over the bandgap energy.

- Strain Engineering: Introducing strain during epitaxial growth modifies the bandgap, enabling further customization of the wavelength.

4. Advanced Materials and Emerging Trends

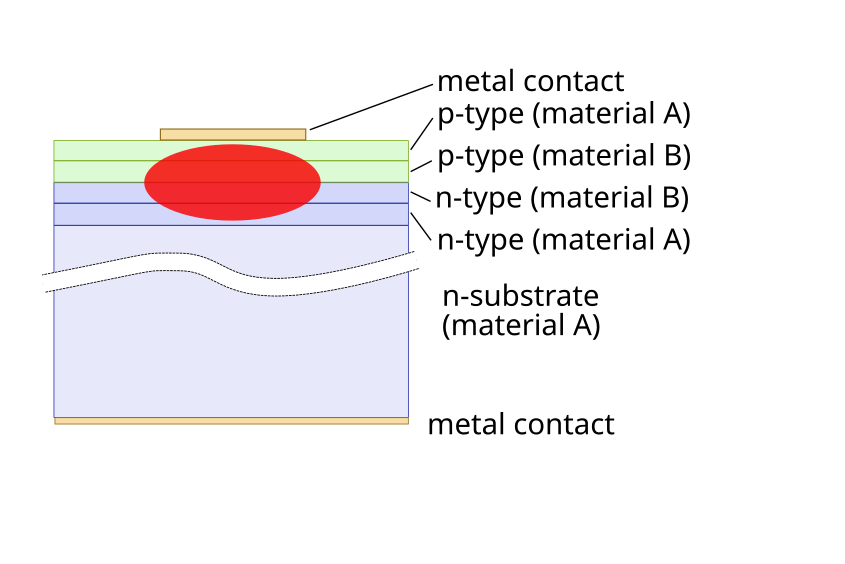

Recent advancements have introduced new wafer materials and structures, such as quantum wells, quantum dots, and two-dimensional materials like graphene. These materials allow for highly efficient lasers with tailored wavelengths and broader functionality.

5. Summary

The choice of wafer material is pivotal in determining the output wavelength of a semiconductor laser. Understanding the relationship between the material’s bandgap and the emitted wavelength allows for precise design and optimization of lasers for diverse applications. As material science continues to evolve, the range and efficiency of semiconductor lasers are expected to expand, opening new possibilities in technology and industry.

TO Packages

TO Packages

Semiconductor Laser

Semiconductor Laser

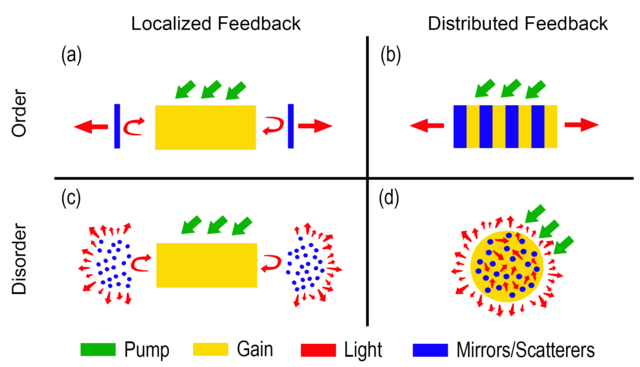

DFB Laser

DFB Laser

LiDAR Technology

LiDAR Technology